The advent of 3D printing technology has revolutionized various industries, including manufacturing and interior design.

Among its many applications, the production of PVC marble sheets stands out as an innovative and transformative process.

3D printed PVC marble sheets offer unparalleled design versatility, cost-effectiveness, and environmental sustainability, making them a sought-after material for modern interior decor.

In this essay, we delve into the manufacturing process of 3D printed PVC marble sheets,

exploring the steps involved, the materials used, the benefits it offers, and its implications for the future of interior design.

The Genesis of 3D Printed PVC Marble Sheets

The journey from virtual to reality in the manufacturing process of 3D printed PVC marble sheets begins with digital design.

Skilled designers utilize computer-aided design (CAD) software to create intricate and realistic marble patterns.

These digital designs serve as the blueprint for the subsequent stages of production.

The CAD files can be easily modified and customized to suit various applications, allowing for exceptional flexibility in design.

The Layer-by-Layer Fabrication Process

The hallmark of 3D printing is the layer-by-layer fabrication technique, also known as additive manufacturing.

The process starts with a roll of PVC (polyvinyl chloride) material, which acts as the base for the marble sheets.

The PVC is fed into the 3D printer, and the CAD file is sent to the printer’s software for slicing, a process that divides the digital design into numerous horizontal layers.

Once the slicing is complete, the 3D printer’s nozzle starts depositing the first layer of PVC, following the design’s specifications.

The printer then proceeds to add successive layers, each fusing seamlessly with the one beneath it.

This additive approach allows for precise control over the marble pattern’s intricate details, ensuring a lifelike and visually stunning final product.

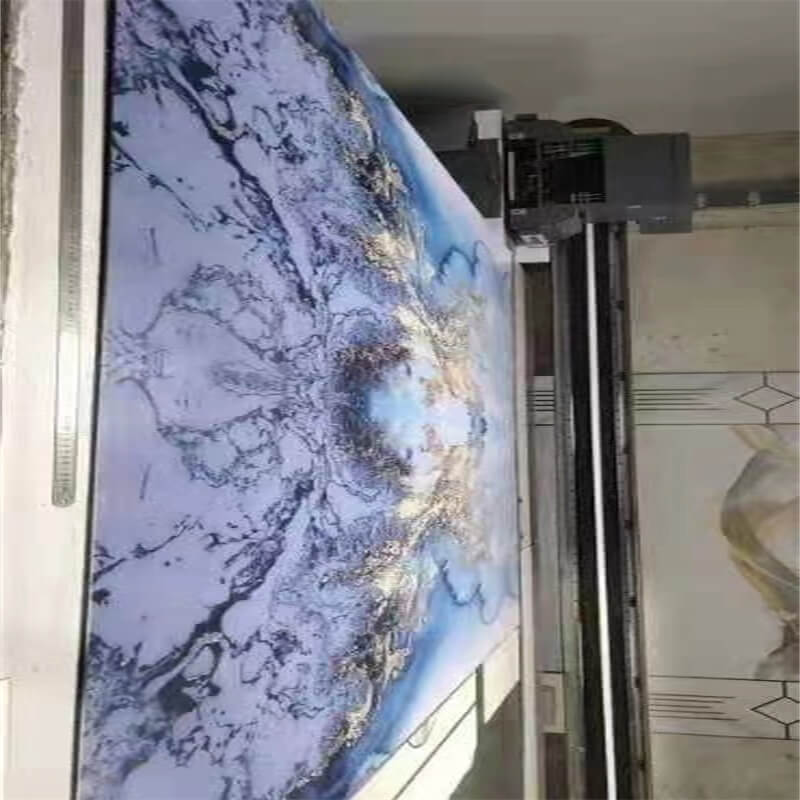

The Role of Digital Inkjet Printing Technology

To achieve the striking marble patterns and colors, digital inkjet printing technology comes into play during the 3D printing process.

Once the base PVC layers are in place, the printer utilizes inkjet heads to apply a layer of vibrant and realistic colors onto the PVC surface.

The ink adheres firmly to the PVC, resulting in a durable and visually appealing marble effect.

The digital inkjet printing technology also offers the advantage of customization.

Designers can experiment with various color combinations and patterns, catering to individual preferences and specific interior design themes.

This level of personalization elevates the appeal of 3D printed PVC marble sheets, making them a popular choice for architects, interior designers, and homeowners alike.

Post-Processing and Quality Control

After the 3D printing and inkjet printing stages, post-processing steps are undertaken to refine the PVC marble sheets further.

Trimming and cutting processes are employed to achieve the desired sheet sizes, and any imperfections are addressed during this stage.

Quality control measures are rigorously applied to ensure that each sheet meets the required standards of durability, visual aesthetics, and safety.

Additionally, certain surface treatments may be applied to enhance the sheet’s properties, such as scratch resistance and UV protection.

These treatments bolster the longevity and performance of the 3D printed PVC marble sheets, making them suitable for various applications, including wall cladding, flooring, and furniture surfaces.

The manufacturing process of 3D printed PVC marble sheets represents a seamless integration of cutting-edge technology and artistic craftsmanship.

From the initial digital design to the additive layer-by-layer fabrication and digital inkjet printing,

each step contributes to the creation of a visually stunning, versatile, and sustainable material for interior design.

The ability to transform virtual designs into reality with such precision has opened new horizons for creativity and innovation in the world of interior decor.

As the technology continues to advance and become more accessible, the future holds tremendous potential for further expanding the applications of 3D printed PVC marble sheets,

allowing for boundless possibilities in interior design and architectural spaces.